Unveiling the Essence of Quality: A Comprehensive Exploration

In today’s rapidly evolving world, the term “quality” is frequently invoked across diverse sectors, from manufacturing and technology to services and education. But what exactly does quality mean? Beyond a simple descriptor, quality embodies a multifaceted concept, encompassing excellence, reliability, and fitness for purpose. This article delves into the core principles of quality, exploring its various dimensions, significance, and the methods employed to achieve and maintain it. Understanding quality is crucial for businesses aiming to thrive, consumers seeking value, and individuals striving for personal and professional growth.

Defining Quality: A Multifaceted Concept

Defining quality is not as straightforward as it may seem. Its meaning is often subjective and context-dependent. However, several key attributes consistently emerge when discussing quality:

- Performance: How well a product or service performs its intended function.

- Reliability: The consistency and dependability of performance over time.

- Durability: The lifespan of a product or service.

- Features: The specific attributes or characteristics that enhance functionality.

- Aesthetics: The visual appeal and design of a product or service.

- Serviceability: The ease with which a product or service can be repaired or maintained.

- Perceived Quality: The overall reputation and brand image associated with a product or service.

- Conformance to Standards: The degree to which a product or service meets established specifications and regulations.

These attributes collectively contribute to the overall perception of quality. A product or service that excels in these areas is generally considered to be of high quality.

The Importance of Quality Across Industries

The pursuit of quality is paramount across all industries. Its impact extends beyond mere customer satisfaction, influencing profitability, brand reputation, and long-term sustainability.

Manufacturing

In manufacturing, quality control is essential for ensuring that products meet specified standards and customer expectations. Defective products can lead to costly recalls, damage brand reputation, and even pose safety risks. Implementing robust quality management systems, such as Six Sigma and Lean Manufacturing, enables manufacturers to minimize defects, optimize processes, and enhance overall quality.

Healthcare

In healthcare, quality is a matter of life and death. High-quality healthcare services are characterized by accurate diagnoses, effective treatments, and compassionate care. Healthcare providers must adhere to rigorous standards of quality to ensure patient safety and positive outcomes. [See also: Healthcare Quality Improvement Strategies]

Education

Quality education is crucial for individual and societal development. A high-quality education system provides students with the knowledge, skills, and critical thinking abilities necessary to succeed in the 21st century. Quality in education encompasses factors such as curriculum design, teacher effectiveness, and access to resources.

Technology

In the technology sector, quality software and hardware are essential for delivering reliable and user-friendly experiences. Bugs, glitches, and security vulnerabilities can significantly impact user satisfaction and damage a company’s reputation. Thorough testing, rigorous code reviews, and adherence to quality assurance principles are crucial for developing high-quality technology products.

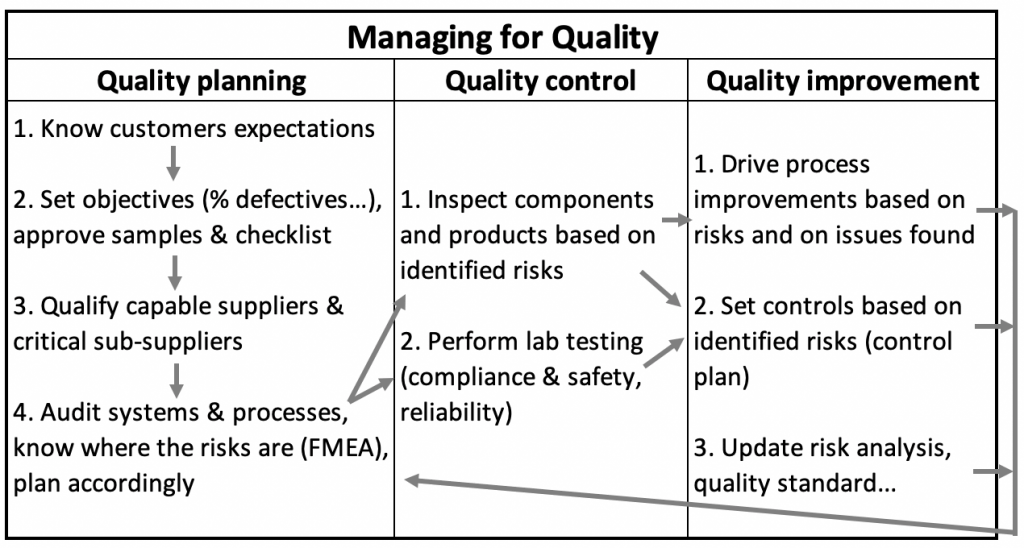

Achieving and Maintaining Quality: Key Strategies

Achieving and maintaining quality requires a commitment to continuous improvement and a systematic approach. Several key strategies can help organizations enhance quality across all aspects of their operations:

Quality Management Systems (QMS)

Implementing a quality management system (QMS) provides a framework for establishing and maintaining quality standards. ISO 9001 is a widely recognized international standard for QMS, providing guidelines for organizations to develop and implement effective quality management processes. A QMS helps organizations document their processes, identify areas for improvement, and ensure consistent quality across all operations.

Statistical Process Control (SPC)

Statistical process control (SPC) uses statistical methods to monitor and control processes. By tracking key metrics and identifying variations, SPC helps organizations identify and address potential quality problems before they occur. SPC tools, such as control charts and histograms, provide valuable insights into process performance and enable data-driven decision-making. [See also: Implementing Statistical Process Control]

Total Quality Management (TQM)

Total quality management (TQM) is a management approach that focuses on continuous improvement and customer satisfaction. TQM emphasizes the involvement of all employees in the pursuit of quality and promotes a culture of continuous learning and improvement. TQM principles include customer focus, process management, employee empowerment, and continuous improvement.

Six Sigma

Six Sigma is a data-driven methodology for improving quality by reducing variation and eliminating defects. Six Sigma projects typically follow a structured approach known as DMAIC (Define, Measure, Analyze, Improve, Control). Six Sigma tools and techniques help organizations identify the root causes of defects and implement solutions to prevent them from recurring. The goal of Six Sigma is to achieve near-perfect quality, with a defect rate of no more than 3.4 defects per million opportunities.

Lean Manufacturing

Lean manufacturing focuses on eliminating waste and maximizing efficiency in the production process. By streamlining processes and reducing waste, Lean manufacturing helps organizations improve quality, reduce costs, and increase customer satisfaction. Lean principles include value stream mapping, just-in-time production, and continuous improvement.

The Role of Technology in Enhancing Quality

Technology plays an increasingly important role in enhancing quality across various industries. Automation, data analytics, and artificial intelligence (AI) are transforming the way organizations manage quality and improve their processes.

Automation

Automation can improve quality by reducing human error and ensuring consistent performance. Automated systems can perform repetitive tasks with greater accuracy and speed than humans, leading to fewer defects and higher quality products. In manufacturing, robots and automated machines are used for tasks such as assembly, inspection, and packaging.

Data Analytics

Data analytics provides valuable insights into process performance and helps organizations identify areas for improvement. By analyzing large datasets, organizations can identify patterns, trends, and anomalies that may indicate potential quality problems. Data analytics tools can be used to monitor process performance, predict defects, and optimize processes for maximum quality.

Artificial Intelligence (AI)

AI is increasingly being used to improve quality in various industries. AI-powered systems can analyze data, identify patterns, and make predictions with greater accuracy than humans. In manufacturing, AI is used for tasks such as defect detection, predictive maintenance, and process optimization. In healthcare, AI is used for tasks such as diagnosis, treatment planning, and drug discovery. The use of AI can lead to significant improvements in quality and efficiency. [See also: AI in Quality Assurance]

The Human Element in Quality

While technology plays a crucial role in enhancing quality, the human element remains essential. Employees are the driving force behind quality improvement initiatives, and their skills, knowledge, and motivation are critical to success. Organizations must invest in training and development to ensure that employees have the skills and knowledge necessary to perform their jobs effectively and contribute to quality improvement efforts.

Furthermore, fostering a culture of quality is essential for long-term success. A quality culture is one in which all employees are committed to quality and continuously strive to improve their performance. This requires strong leadership, clear communication, and a commitment to employee empowerment. When employees feel valued and empowered, they are more likely to take ownership of quality and contribute to continuous improvement efforts.

The Future of Quality

The future of quality is likely to be shaped by several key trends, including the increasing use of technology, the growing importance of sustainability, and the evolving expectations of customers.

As technology continues to advance, organizations will increasingly rely on automation, data analytics, and AI to improve quality and efficiency. The use of these technologies will enable organizations to achieve higher levels of quality and reduce costs. Sustainability will also become an increasingly important consideration, as customers demand products and services that are environmentally friendly and socially responsible. Organizations that prioritize sustainability will be better positioned to meet the evolving expectations of customers and maintain a competitive advantage. Finally, the expectations of customers will continue to evolve, as they demand higher levels of quality, personalization, and convenience. Organizations that are able to adapt to these evolving expectations will be best positioned to succeed in the future.

Conclusion

Quality is a multifaceted concept that encompasses excellence, reliability, and fitness for purpose. It is essential across all industries and plays a critical role in determining the success of organizations. Achieving and maintaining quality requires a commitment to continuous improvement, a systematic approach, and the effective use of technology. By implementing quality management systems, utilizing statistical process control, and fostering a culture of quality, organizations can enhance their performance, improve customer satisfaction, and achieve long-term sustainability. As technology continues to advance and customer expectations evolve, the pursuit of quality will remain a critical imperative for organizations seeking to thrive in the 21st century. The unwavering commitment to quality is not just a business strategy; it’s a fundamental principle for creating value and building a better world.