Headless Compression Screw: A Comprehensive Guide for Modern Engineering

In modern engineering, the demand for compact, efficient, and reliable fastening solutions is ever-increasing. The headless compression screw emerges as a critical component in various applications, offering a unique set of advantages over traditional screws and fasteners. This comprehensive guide delves into the intricacies of headless compression screws, exploring their design, functionality, applications, benefits, and considerations for selection and implementation. Understanding the nuances of headless compression screws is essential for engineers, designers, and manufacturers aiming to optimize their designs and improve overall performance.

What is a Headless Compression Screw?

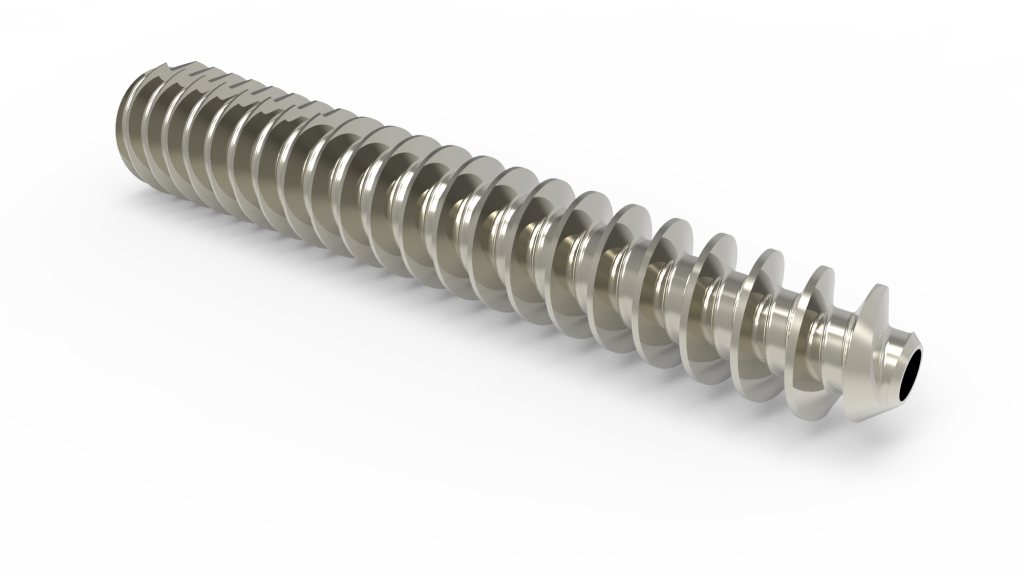

A headless compression screw, also known as a setscrew or grub screw, is a type of fastener that is fully threaded and lacks a head. Instead of a protruding head that sits above the surface of the fastened components, the headless compression screw is designed to be entirely embedded within a tapped hole. These screws are typically used to secure an object within or against another object without the need for a traditional bolt head. The primary function of a headless compression screw is to exert compressive force, thereby preventing relative movement between the joined parts.

The design of a headless compression screw usually incorporates a drive feature, such as a hex socket (Allen key), a slotted drive, or a Torx drive, allowing for installation and adjustment using appropriate tools. This recessed drive mechanism further contributes to the screw’s ability to be fully concealed, making it ideal for applications where a flush or near-flush surface is required.

Key Features and Design Considerations

Several design features distinguish headless compression screws from other types of fasteners:

- Headless Design: The absence of a head allows for complete embedding within the material, providing a clean, unobtrusive appearance.

- Full Threading: The entire body of the screw is threaded, maximizing the contact area and enhancing the holding power.

- Drive Types: Available in various drive types (hex socket, slotted, Torx) to accommodate different installation requirements and torque levels.

- Material Options: Typically manufactured from materials like stainless steel, alloy steel, and brass to suit different environmental conditions and load requirements.

- Point Styles: The end of the screw can be shaped into different point styles (cup point, cone point, flat point, knurled cup point) to optimize grip and prevent damage to the mating surface.

When selecting a headless compression screw, several design considerations are crucial:

- Material Compatibility: Ensure the screw material is compatible with the materials being joined to prevent corrosion or galvanic reactions.

- Load Requirements: Determine the required clamping force and select a screw with adequate strength and thread engagement.

- Environmental Conditions: Consider factors such as temperature, humidity, and exposure to chemicals when choosing the screw material and finish.

- Drive Type: Select a drive type that allows for easy installation and adjustment, considering the available tools and accessibility.

- Point Style: Choose a point style that provides the desired level of grip without damaging the mating surface. For instance, a cup point offers good grip, while a flat point is less likely to mar the surface.

Applications of Headless Compression Screws

Headless compression screws are utilized across a wide range of industries and applications due to their versatility and functional benefits. Some notable applications include:

- Machine Components: Securing gears, pulleys, and knobs to shafts in machinery.

- Tooling and Fixtures: Adjusting and locking components in jigs, fixtures, and molds.

- Medical Devices: Fastening components in medical instruments and implants where a smooth, unobtrusive surface is required.

- Consumer Electronics: Securing internal components in electronic devices where space is limited and aesthetics are important.

- Automotive Industry: Adjusting and securing components in automotive assemblies.

- Aerospace Engineering: Used in various aerospace applications where weight and space are critical considerations.

In each of these applications, the headless compression screw provides a reliable and efficient fastening solution that meets the specific requirements of the design.

Advantages of Using Headless Compression Screws

The use of headless compression screws offers several advantages over traditional fasteners:

- Compact Design: The absence of a head allows for a more compact and streamlined design, which is particularly beneficial in space-constrained applications.

- Flush Surface: The screw can be fully embedded within the material, providing a flush or near-flush surface that eliminates protrusions and enhances aesthetics.

- Secure Fastening: The full threading and various point styles provide a secure and reliable fastening solution that prevents loosening due to vibration or other external forces.

- Adjustability: The recessed drive mechanism allows for easy adjustment and re-tightening as needed.

- Versatility: Available in a wide range of materials, sizes, and drive types to suit different applications and requirements.

- Reduced Risk of Injury: The flush surface minimizes the risk of snagging or injury compared to protruding bolt heads.

These advantages make headless compression screws a preferred choice in many modern engineering designs.

Types of Headless Compression Screw Points

The point style of a headless compression screw is critical for its performance. Different point styles offer varying degrees of grip and surface protection. Here are some common types:

- Cup Point: This is the most common type, featuring a concave cup shape that provides excellent grip. The edges of the cup dig into the mating surface, creating a secure hold.

- Cone Point: This type has a pointed end that is ideal for applications where precise alignment is required. The cone point can be inserted into a pre-drilled dimple to provide accurate positioning.

- Flat Point: The flat point is designed to provide a smooth, non-marring contact surface. It is suitable for applications where damage to the mating surface must be avoided.

- Knurled Cup Point: This type features a cup point with knurled edges, providing enhanced grip and resistance to loosening.

- Dog Point: Also known as a shoulder point, this type has a cylindrical extension that fits into a hole to provide precise alignment and prevent movement.

Selecting the appropriate point style is essential for optimizing the performance and longevity of the headless compression screw.

Materials Used in Headless Compression Screws

The choice of material for a headless compression screw depends on the specific requirements of the application, including load, environment, and compatibility with other materials. Common materials include:

- Stainless Steel: Offers excellent corrosion resistance and is suitable for applications in harsh environments. Various grades of stainless steel are available, each with different properties and levels of corrosion resistance.

- Alloy Steel: Provides high strength and is often used in applications where high loads are expected. Alloy steel screws are typically heat-treated to enhance their strength and durability.

- Carbon Steel: A cost-effective option for general-purpose applications. Carbon steel screws are often coated with zinc or other protective finishes to prevent corrosion.

- Brass: Offers good corrosion resistance and is often used in electrical applications due to its conductivity. Brass screws are also non-magnetic, making them suitable for sensitive electronic equipment.

- Nylon: A non-metallic option that is lightweight and corrosion-resistant. Nylon screws are often used in applications where electrical insulation is required.

The material selection process should consider the long-term performance and reliability of the headless compression screw in the intended application.

Installation and Removal Techniques

Proper installation and removal techniques are essential for ensuring the optimal performance and longevity of headless compression screws.

Installation:

- Prepare the Hole: Ensure the tapped hole is clean and free of debris. Use a tap to create or clean the threads if necessary.

- Select the Correct Tool: Use the appropriate tool for the drive type (e.g., Allen key for hex socket screws, screwdriver for slotted screws).

- Apply Torque: Apply the recommended torque to achieve the desired clamping force without over-tightening. Over-tightening can damage the screw or the mating material.

- Verify Engagement: Ensure the screw is fully engaged and properly seated in the hole.

Removal:

- Use the Correct Tool: Use the appropriate tool for the drive type.

- Apply Penetrating Oil: If the screw is stuck or corroded, apply penetrating oil to loosen the threads.

- Apply Steady Pressure: Apply steady pressure while turning the screw to avoid stripping the drive.

- Use a Screw Extractor: If the drive is stripped, use a screw extractor to remove the screw.

Following these techniques will help ensure the successful installation and removal of headless compression screws.

Troubleshooting Common Issues

Despite their reliability, headless compression screws can sometimes encounter issues. Here are some common problems and their solutions:

- Stripped Drive: If the drive is stripped, use a screw extractor to remove the screw. Prevent this by using the correct tool and applying steady pressure during installation and removal.

- Corrosion: If the screw is corroded, apply penetrating oil and use a wrench to gently loosen it. Prevent this by using corrosion-resistant materials and applying protective coatings.

- Loosening: If the screw loosens over time, use a locking compound or a knurled cup point screw to provide enhanced grip.

- Damage to Mating Surface: If the screw damages the mating surface, use a flat point screw or reduce the clamping force.

Future Trends in Headless Compression Screw Technology

The field of fastener technology is constantly evolving, and headless compression screws are no exception. Future trends include:

- Smart Screws: Integration of sensors and electronics to monitor clamping force and detect loosening.

- Advanced Materials: Development of new materials with enhanced strength, corrosion resistance, and biocompatibility.

- Additive Manufacturing: Use of additive manufacturing techniques to create custom screw designs and geometries.

- Self-Locking Mechanisms: Incorporation of self-locking mechanisms to prevent loosening due to vibration or other external forces.

These advancements will further enhance the performance and versatility of headless compression screws in various applications.

Conclusion

The headless compression screw is a versatile and essential component in modern engineering. Its compact design, secure fastening, and adjustability make it a preferred choice in a wide range of applications. By understanding the design considerations, material options, and installation techniques, engineers and designers can effectively utilize headless compression screws to optimize their designs and improve overall performance. As technology continues to advance, the future of headless compression screws promises even greater innovation and functionality. Whether you’re securing machine components, adjusting tooling fixtures, or fastening medical devices, the headless compression screw offers a reliable and efficient solution for your fastening needs. [See also: Types of Fasteners in Mechanical Engineering] [See also: Screw Thread Standards Explained]