Unlocking the Power of Cycle Hydraulic Brakes: A Comprehensive Guide

In the realm of cycling, safety and control are paramount. Among the various components contributing to a secure and enjoyable ride, the braking system stands out as arguably the most crucial. While traditional cable brakes have served cyclists for decades, cycle hydraulic brakes have emerged as a superior alternative, offering enhanced performance, reliability, and modulation. This comprehensive guide delves into the intricacies of cycle hydraulic brakes, exploring their workings, advantages, disadvantages, maintenance, and suitability for different cycling disciplines.

Understanding Cycle Hydraulic Brakes

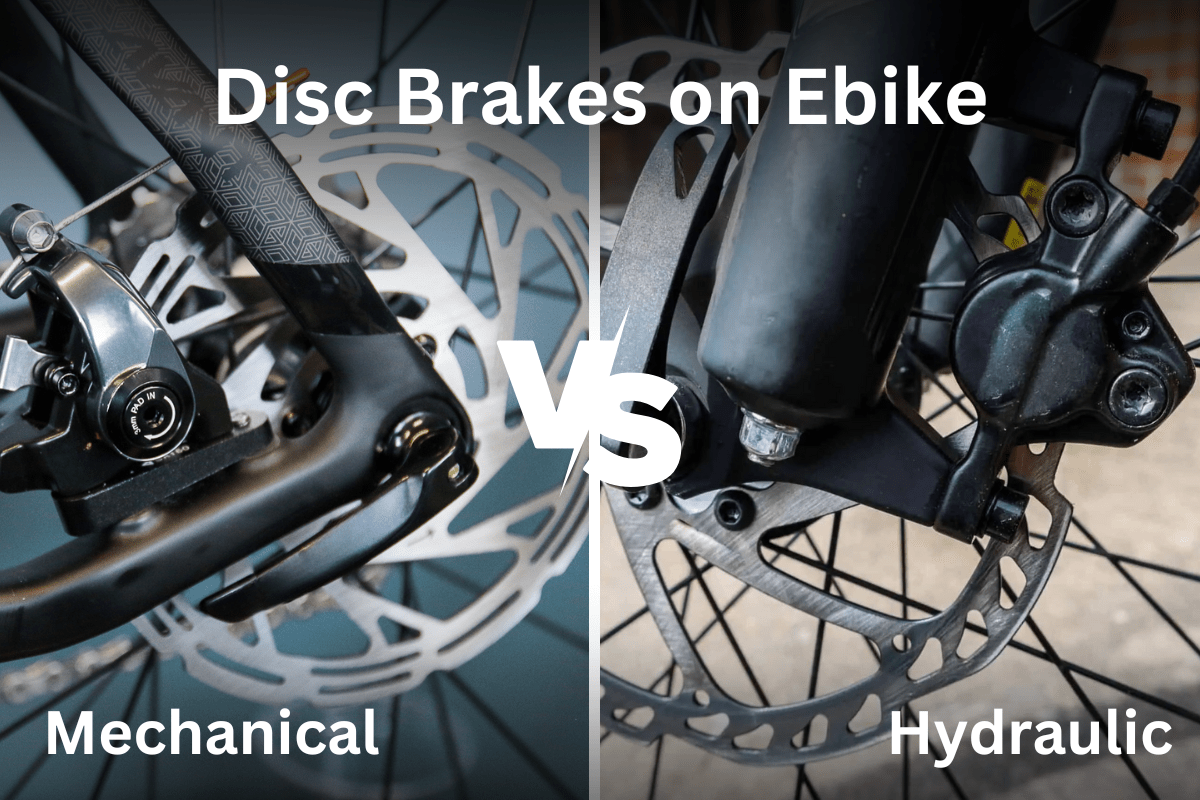

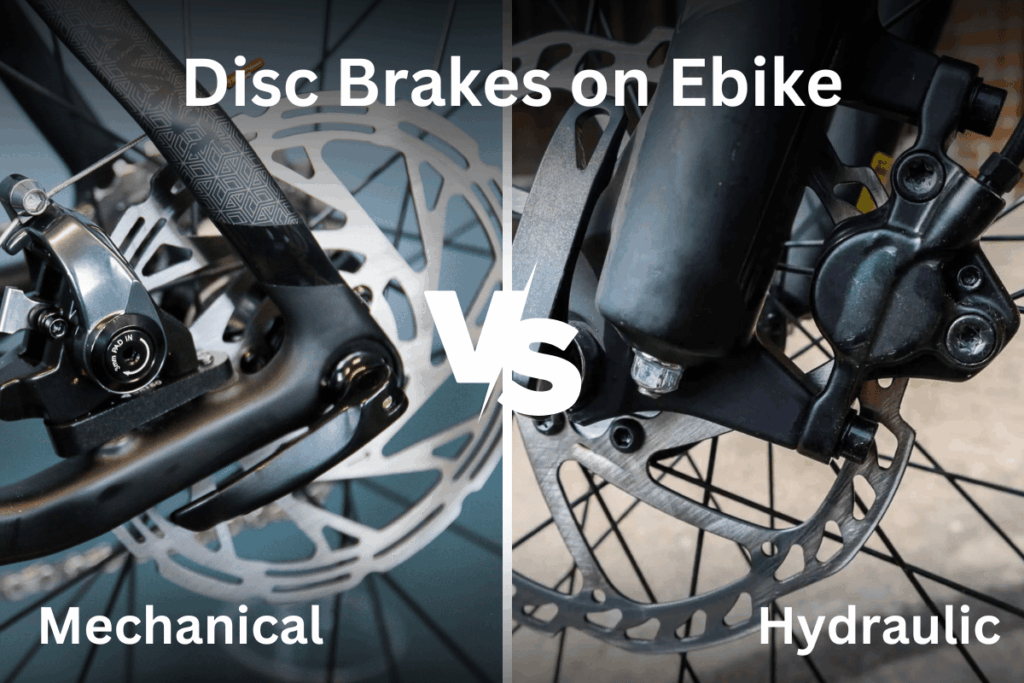

Cycle hydraulic brakes utilize a closed system containing brake fluid to transmit force from the brake lever to the brake caliper. When the lever is squeezed, it pushes a piston within the master cylinder, pressurizing the brake fluid. This pressure is then transmitted through hoses to the caliper, where it forces pistons to push the brake pads against the rotor, generating friction and slowing or stopping the bicycle. Unlike cable brakes, which rely on mechanical force transmitted through a cable, cycle hydraulic brakes offer a more direct and efficient transfer of power.

Key Components of a Hydraulic Brake System

- Brake Lever: The interface between the rider and the braking system, allowing for modulation of braking force.

- Master Cylinder: Located at the brake lever, it contains a piston that pressurizes the brake fluid when the lever is activated.

- Brake Fluid: A specialized fluid designed to withstand high temperatures and pressures, transmitting force throughout the system.

- Brake Hoses: Connect the master cylinder to the caliper, carrying the pressurized brake fluid.

- Caliper: Houses the pistons that push the brake pads against the rotor.

- Brake Pads: Friction material that engages with the rotor to create braking force.

- Rotor: A metal disc attached to the wheel hub, providing a surface for the brake pads to grip.

Advantages of Cycle Hydraulic Brakes

Cycle hydraulic brakes offer several distinct advantages over traditional cable brakes, contributing to improved performance and safety:

- Enhanced Stopping Power: The direct transfer of force through brake fluid results in significantly greater stopping power, particularly in wet or muddy conditions.

- Improved Modulation: Cycle hydraulic brakes provide superior modulation, allowing riders to precisely control braking force and avoid locking up the wheels. This is especially important for technical terrain and emergency braking situations.

- Reduced Maintenance: Unlike cable brakes, which require regular cable adjustments and replacements, cycle hydraulic brakes are relatively low-maintenance. The sealed system prevents contamination and minimizes the need for adjustments.

- Consistent Performance: Cycle hydraulic brakes maintain consistent performance regardless of weather conditions or cable stretch, ensuring reliable braking in all situations.

- Lighter Lever Action: The hydraulic system requires less force to activate the brakes, reducing hand fatigue and improving rider comfort, especially on long descents.

- Self-Adjusting: Hydraulic brakes are self-adjusting to account for brake pad wear, meaning you don’t have to constantly adjust the brake cable tension as the pads wear down.

Disadvantages of Cycle Hydraulic Brakes

While cycle hydraulic brakes offer numerous advantages, they also have some potential drawbacks to consider:

- Higher Cost: Cycle hydraulic brakes are generally more expensive than cable brakes, both in terms of initial purchase price and potential repair costs.

- More Complex Maintenance: While low-maintenance overall, when issues do arise, hydraulic brake systems require specialized tools and knowledge to service properly. Bleeding the brakes, for example, is a more complex process than adjusting cable tension.

- Potential for Leaks: Although rare, hydraulic systems can be susceptible to leaks, which can compromise braking performance.

- Weight: While the difference is often negligible, some hydraulic brake systems can be slightly heavier than their cable-operated counterparts.

Choosing the Right Cycle Hydraulic Brakes

Selecting the appropriate cycle hydraulic brakes depends on several factors, including the type of cycling you engage in, your budget, and your personal preferences.

Considerations for Different Cycling Disciplines

- Mountain Biking: Mountain bikes benefit greatly from the increased stopping power and modulation of cycle hydraulic brakes, especially for aggressive trail riding and downhill racing. Look for brakes with larger rotors and more powerful calipers.

- Road Cycling: Road bikes are increasingly equipped with hydraulic disc brakes, offering improved braking performance in all weather conditions. Aerodynamic considerations and weight savings are important factors to consider.

- Gravel Cycling: Gravel bikes often encounter varied terrain and unpredictable conditions, making cycle hydraulic brakes a desirable upgrade for enhanced control and confidence.

- Commuting/Urban Cycling: Hydraulic disc brakes provide reliable stopping power in urban environments, where quick stops and unpredictable traffic are common.

Factors to Consider

- Braking Power: Choose brakes with sufficient stopping power for your riding style and the types of terrain you encounter.

- Modulation: Look for brakes that offer smooth and predictable modulation, allowing you to precisely control braking force.

- Lever Feel: Consider the lever feel and ergonomics, ensuring that the brakes are comfortable and easy to use.

- Rotor Size: Larger rotors provide greater stopping power and heat dissipation, but they can also add weight.

- Brand Reputation: Research different brands and read reviews to ensure that you are choosing a reputable and reliable product.

- Budget: Cycle hydraulic brakes range in price, so set a budget and find the best option within your price range.

Maintaining Your Cycle Hydraulic Brakes

Proper maintenance is essential for ensuring the longevity and performance of your cycle hydraulic brakes.

Regular Inspections

Periodically inspect your brakes for any signs of leaks, damage, or excessive wear. Check the brake pads for wear and replace them when necessary. Also, inspect the brake hoses for cracks or bulges.

Brake Bleeding

Brake bleeding is the process of removing air bubbles from the hydraulic system. Air bubbles can compromise braking performance and lead to a spongy lever feel. Bleed your brakes when you notice a decrease in braking power or a spongy lever feel. This is best performed by a qualified mechanic unless you have experience with the process.

Brake Pad Replacement

Replace your brake pads when they are worn down to the wear indicators. Using worn brake pads can damage the rotors and reduce braking performance. Different types of brake pads exist, including organic and sintered, each with different performance characteristics. [See also: Understanding Brake Pad Materials]

Cleaning

Keep your brakes clean and free of dirt and debris. Use a mild detergent and water to clean the calipers and rotors. Avoid using harsh chemicals or solvents, as they can damage the seals and hoses.

Proper Storage

When storing your bicycle for extended periods, ensure that the brakes are properly protected. Avoid storing the bicycle in direct sunlight or extreme temperatures, as this can damage the brake fluid and hoses.

Troubleshooting Common Issues

Even with proper maintenance, you may encounter some common issues with your cycle hydraulic brakes.

Spongy Lever Feel

A spongy lever feel is often caused by air in the hydraulic system. Bleeding the brakes will typically resolve this issue.

Weak Braking Power

Weak braking power can be caused by worn brake pads, contaminated rotors, or air in the hydraulic system. Check the brake pads and rotors for contamination and bleed the brakes if necessary.

Brake Squeal

Brake squeal can be caused by contaminated rotors or brake pads. Clean the rotors and brake pads with a mild detergent and water. If the squeal persists, you may need to replace the brake pads.

Leaking Brakes

Leaking brakes are a serious issue that requires immediate attention. Inspect the brake hoses, calipers, and master cylinder for leaks. If you find a leak, take your bicycle to a qualified mechanic for repair.

The Future of Cycle Hydraulic Brakes

Cycle hydraulic brakes continue to evolve, with manufacturers constantly developing new technologies to improve performance, reliability, and ease of use. Wireless hydraulic brakes, for example, are eliminating the need for hoses, further simplifying installation and maintenance. As technology advances, cycle hydraulic brakes will undoubtedly become even more prevalent in the cycling world, offering riders unparalleled control and confidence on the road and trail. [See also: Future of Bicycle Technology]

Conclusion

Cycle hydraulic brakes represent a significant advancement in bicycle braking technology, offering superior stopping power, modulation, and reliability compared to traditional cable brakes. While they may require a higher initial investment and more complex maintenance, the benefits they provide in terms of safety and performance are undeniable. Whether you are a seasoned mountain biker, a dedicated road cyclist, or a casual commuter, cycle hydraulic brakes can enhance your riding experience and provide you with the confidence you need to tackle any challenge.